One-Sentence Definition

First Article Inspection (FAI) is a comprehensive quality validation process that verifies whether the first manufactured product from a new or modified production process meets all specified engineering and customer requirements.

Detailed Explanation

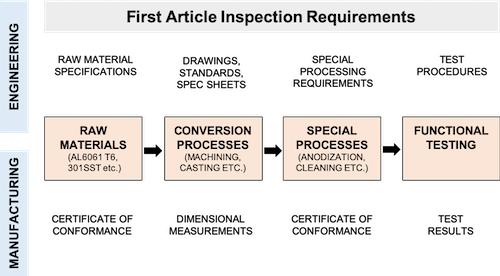

FAI is a critical step in manufacturing, especially for custom and high-precision products. It involves a thorough inspection and documentation of the first item produced, ensuring that every dimension, material, and functional aspect aligns with technical drawings and customer specifications. This process is essential for both suppliers and buyers: suppliers confirm their manufacturing process is capable and stable, while buyers gain confidence that future mass production will consistently meet their standards. FAI is not a one-time event; it is required whenever there are changes in design, materials, processes, equipment, or after a significant production gap (source, 1Factory Guide).

Key Components of FAI

Engineering Documentation Review: Verification of drawings, bills of materials, and specifications.

Raw Material Traceability: Certification and traceability of all materials used.

Dimensional and Functional Testing: Full measurement of all critical dimensions and functional tests using calibrated equipment (e.g., CMMs, calipers).

FAI Report (FAIR): Standardized documentation, often following the AS9102 format, including:

Form 1: Part Number Accountability

Form 2: Product Accountability (materials, processes, tests)

Form 3: Characteristic Accountability (dimensions, tolerances, results)

Balloon Drawing: Visual mapping of all inspected features (Engineering.com)

Customer and Quality Approval: Review and sign-off by both internal quality teams and the customer.

Real-World Application: FAI in Custom Acrylic Manufacturing

For companies like Toyin Acrylic Products Co., Ltd. (TOYIN), FAI is vital in custom acrylic product manufacturing. Before mass-producing items such as display stands or protective covers for international brands, TOYIN conducts a full FAI on the first sample. This includes verifying all design details, material certifications, and functional performance. The FAI report is then shared with the client for approval, ensuring that any issues are addressed before large-scale production begins. This process minimizes the risk of costly defects, enhances customer trust, and supports TOYIN’s commitment to high-quality, custom solutions.

Related Concepts

Quality Control (QC): The broader system of checks and processes to ensure product quality throughout manufacturing.

Production Part Approval Process (PPAP): A more extensive process, common in automotive, that includes FAI as a subset but covers broader process validation.

Process Validation: Systematic confirmation that a manufacturing process consistently produces products meeting specifications.

Final Inspection: The last quality check before shipment, distinct from FAI which occurs at the start of production.

Balloon Drawing: A technical drawing where each feature to be inspected is marked with a unique identifier, ensuring traceability in the FAI report.

For more on FAI standards, see SAE AS9102.

Looking for high-quality, custom acrylic products with rigorous quality control? Contact TOYIN for a quote or consultation.