An Introduction to Acrylic Sheets

How Are Acrylic Sheets Classified?

Here are the main classification methods for acrylic sheets:

By Production Process:

Cast Acrylic Sheet: Made by pouring liquid monomer into molds and polymerizing, resulting in high molecular weight, excellent hardness, superior transparency, and strong weather resistance. Ideal for high-end displays and signage.

Extruded Acrylic Sheet: Manufactured through heat extrusion, offering higher production efficiency and lower costs. It has a lower molecular weight and is suitable for applications with less demanding precision requirements, such as light boxes and advertising displays.

By Transparency:

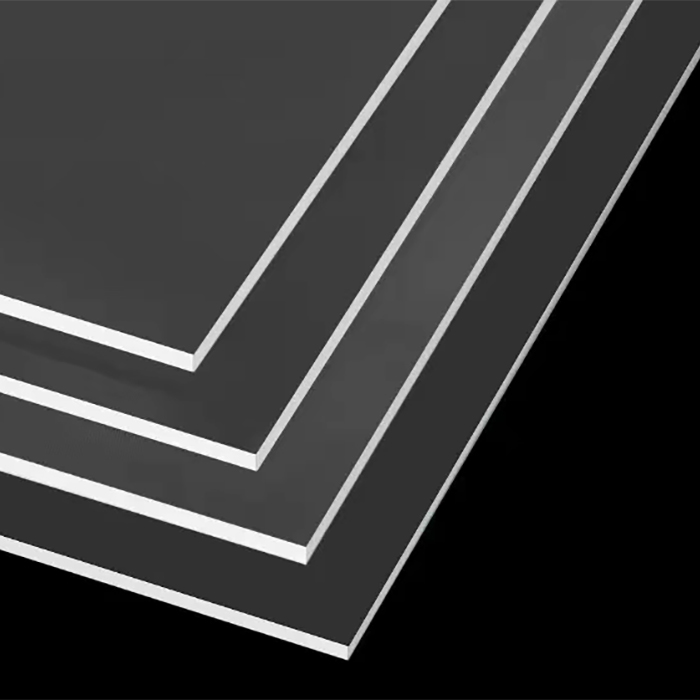

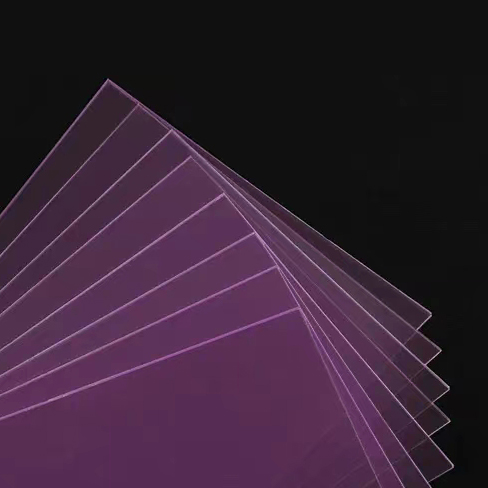

Clear Acrylic Sheet

Colored Acrylic Sheet

Clear Acrylic Sheet: Known for its high transparency, with a light transmission rate of up to 92%. Commonly used for display cases, windows, and signage.

Colored Acrylic Sheet: Produced by adding pigments, available in a variety of colors. Often used for signage, decorative materials, and interior design.

By Surface Finish:

Frosted Acrylic Sheet

Mirrored Acrylic Sheet

Frosted Acrylic Sheet: Surface is frosted for a softer light diffusion, commonly used for partitions and decoration.

Mirrored Acrylic Sheet: Features a reflective surface, ideal for high-end displays and decorative applications.

By Functionality:

UV Resistant Acrylic Sheet: Designed to resist UV light, making it suitable for outdoor advertising and displays.

Flame Retardant Acrylic Sheet: Features flame-resistant properties, ideal for applications with fire safety requirements.

Additional Acrylic Sheet Types

In addition to the common acrylic sheets, we also use:

Glitter Acrylic Sheet

Wave Ripple Sheet

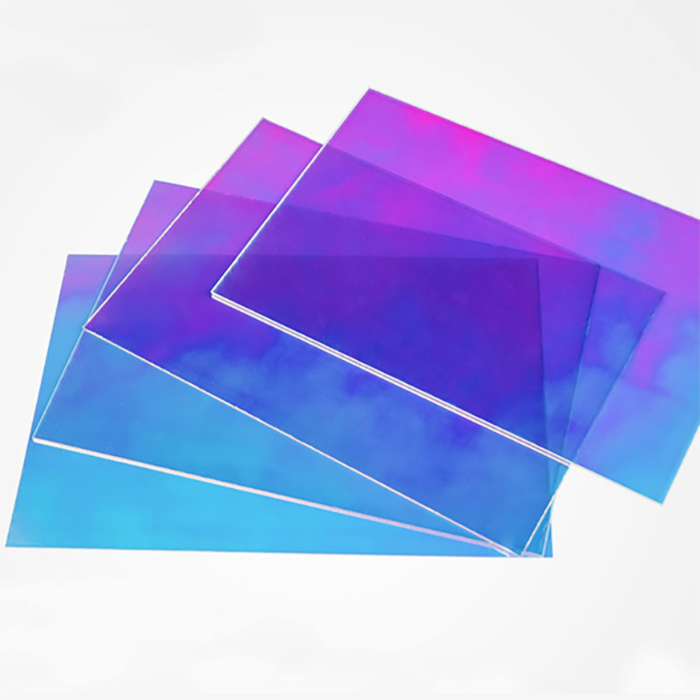

Iridescent Acrylic Sheet

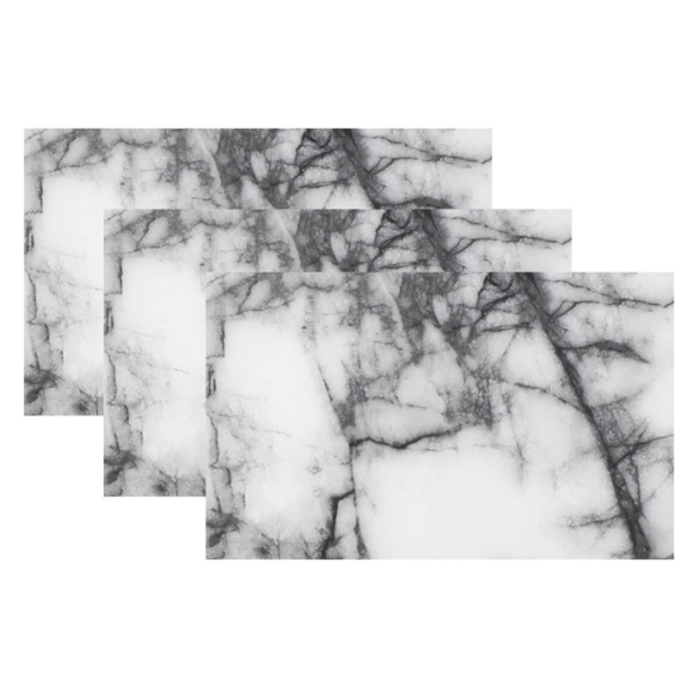

Marble Acrylic Sheet

MS Sheet

PS Sheet

PC Sheet

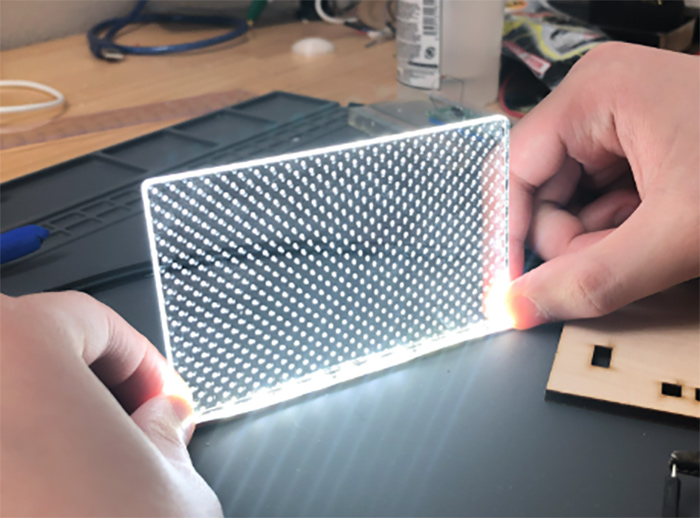

PMMA Light Guide Plate

Glitter Acrylic Sheet: These sheets contain embedded glitter particles, adding a sparkling effect for decorative applications.

Wave Ripple Sheet: Featuring a wavy, rippled texture, these sheets create unique visual effects and are used in artistic and design projects.

Iridescent Acrylic Sheet: These sheets exhibit a color-changing effect when viewed from different angles, offering a dynamic and shifting appearance.

Marble Acrylic Sheet: Mimicking the look of marble, these sheets combine the elegance of marble with the lightweight and durable qualities of acrylic.

MS Sheets: Methyl Styrene sheets provide high impact resistance and clarity, ideal for high-traffic and demanding applications.

PS Sheets: Polystyrene sheets are lightweight and cost-effective, suitable for basic applications where impact resistance is less critical.

PC Sheets: Polycarbonate sheets are known for their high impact resistance and optical clarity, making them suitable for applications requiring durability and strength.

PMMA Light Guide Plates: These plates are used for distributing light evenly in backlighting applications, offering excellent light diffusion properties.